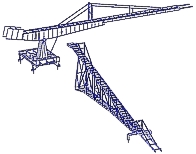

Stacker and tripper-car

The stacker is working in a coal storage and has a maximum throughput of 1,200 m³/h. The boom has an outreach of about 38.3 m and it is mounted luffeable on a rail mounted portal. The tripper car is dragged by the stacker while it brings the feeding conveyor close to the chute of the stacker. Electrical equipment for the tripper car as well as the stacker is mounted on the tripper car.

For both machines preliminary and final design calculations were prepared. Load assumptions and proofs were done according to australian standards.

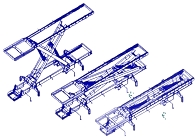

Catering vehicle UNICAT

The catering vehicle UNICAT of Trepel Airport Equipment GmbH is used for loading and unloading catering trolleys on aircrafts. The loader is moving selfpowered on the apron. On the backlift an all around closed van body is mounted. Catering trolley are loaded in lower position and unloaded at height of aircraft sills (or vice versa).

For the relevant structure a KRASTA beam model was generated and calculated for three distinct positions of the upper lift frame. Connection details were designed and analyzed. A final design report for this calculation was prepared.

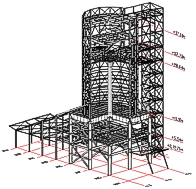

FGD-gypsum storage silo

The gypsum which is a product of flue-gas desulfurization (FGD) in a brown coal power plant is transported by belt conveyors to distribution buildings. From there the Gypsum may be transported to the gypsum silo which is supposed to be an interim storage. The feeding belt conveyor bridge is transporting the gypsum through the stair tower of the silo building. A storage mechanism is placing the gypsum in stock in the silo cell (capacity about 1500m³). The silo floor is designed as a girder grid. Below the silo floor a discharge auger is mounted, which releases the gypsum from stock and delivers the material further into goods wagons.

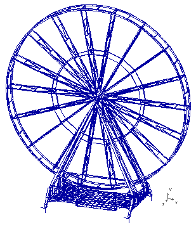

Mobile giant wheel

The giant wheel with a diameter of 38m is designed for easy transport and quick erection. Three semi-trailers are bolted together, the columns are straightened up and the spokes are mounted with the ring beams. The outer ring is pretensioned with hydraulic cylinders so that the spokes stay under tension in all operating situations.

The structure of the giant wheel and the semi-trailers are designed and analysed so that all proofs of strength and stability are met. The pretension of the outer ring was determined, relevant connections were designed according to fatigue considerations. A final design report was prepared for the certification authorities.

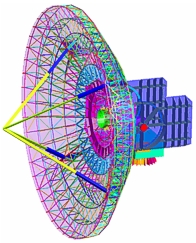

Radiotelescopes 40m, 50m and 64m diameter

For MT Mechatronics GmbH (former MAN Technologie) Kühne BSB GmbH was involved in the design of the supporting structure of three radio telescopes. In close cooperation with the client hybrid beam and shell finite element models were made. These models were used to optimize deformation and vibration behaviour of the parabolic surface and later for static calculations and proofs. For the analysis of complex details further finite element models with sections of the structure were made. The radiotelescopes operate in Spain, Mexico and on Sardinia.